-

Product Information

Interflex Inc. is doing our best to produce accurate and reliable products today.

-

Technical Information

Interflex Inc. is focusing our capacity on the development of new technology to meet various needs of our customers by utilizing accumulated know-how of FPCB and TSP manufacturing technology.

-

Quality/Environment/Ethical Management

Interflex Inc. is conducting items below in order to provide our customers happiness beyond satisfaction.

-

Investment Information

Interflex Inc. is trying to enhance the corporate transparency by disclosing the share price, IR information etc.

-

Corporate Information

Welcome all our guests visiting to Interflex Inc.

-

Hiring Talent

Interflex Inc. is inviting the talent of next generation to open up the future of innovation and changes with us.

Quality/Environment/Ethical Management

HOME > Quality/Environment/Ethical Management > Environment Management

Environment

Management

Interflex Inc., as the leader of flexible printed circuit board (FPCB), recognizes that Environment, compliance with global standards of safety, health, and energy. Our efforts to reduce greenhouse gas emission are the main factors of sustainable management; makes a safe work place with participation of all the members; continues our efforts of complying environment, safety, and health policies and performing regular check-up to provide service to our interest parties

-

Environment, safety and health management

meet domestic and international agreements and laws and enhance health of employees, prevent environment contamination and recycle of resources, perform risk management, and operate the management system of environment/safety/health to realize corporate social responsibilities

-

Risk Management

identify potential risk factors by assessment of environment, safety and health and take actions as necessary so as to remove risk factors that can possibly affect the employees and the community

-

Duty of employees

all the employees shall comply with the environment, safety and health standards in place and the company shall form a corporate culture of environment, safety and health through regular training.

-

Manufacturing of green products

minimize possible impact on environment, safety and health by using green products throughout the overall course of product design, production, use and disposal to meet customers’ requirements

-

Social responsibility

openly disclose the environment, safety and health management activities and make contributions to the community.

Environment Certification

| Class | Year | Description | Remarks |

|---|---|---|---|

| Awards | Exemplary environment management company commendation | 2007 | Ansan-si |

| Evergreen Environment Certification Excellent Site Awards | 2014 | nsan-si | |

| Certification | ISO 14001 Certification | 2002 | KTLMS |

| Evergreen Environment Certification Site, Green Level obtained | 2013 | Ansan-si(Evergreen 21) | |

| ISO 14064-1 Greenhouse Gas Inventory Certification | 2013 | Korea Environment Corporation | |

| Agreements | Autonomous Accident Prevention Partnership Agreements | 2007 | Ansan Division of Kyungin Provincial Department of Labor |

| Samsung Electronics ECO Partnership Agreements | 2007 | Samsung Electronics | |

| Samsung Electro-Mechanics S-Partner Agreements | 2007 | Samsung Electronics | |

| Samsung SDI S-Partner Agreements | 2007 | Samsung SDI | |

| Sony Green Partnership Agreements | 2009 | SONY |

Certification Organization : KTLMS / Korean Environment Public Corporation

Certification Name

ISO 14001

Acquisition Date

Jun. 2002

Certification Name

Greenhouse gas inventory certificate

Acquisition Date

Jun. 2002

Air Quality

Interflex Inc.

has significantly reduced the emission concentration through efforts such as expansion of air pollution prevention facility, pollution reduction facility etc. in order to minimize air pollutants, and is actively responding to interest parties’ requirements in accordance with information by continuous improvement activities and air quality measurement in the adjacent area

Emission Criteria

Based on 2015

| Class | Unit | Emission Allowance Criteria | Emission Concentration | Pollutant Emission Concentration to the Allowance Criteria (%) |

|---|---|---|---|---|

| Dust | ㎎/S㎥ | 40 | 9.42 | 19% |

| SOx | ppm | 400 | 3.58 | 1% |

| HCl | ppm | 5 | 0.71 | 14% |

| Cu | ㎎/S㎥ | 10 | 0.11 | 1% |

| Ni | ㎎/S㎥ | 20 | 0.03 | 0% |

Water Quality

Interflex Inc.

reduces pollutant emission through manufacturing procedure improvement with the optimized processing system (physical and chemical treatment) capable of treating maximum 11,000 tons per day. Also, we’re operating our business by setting up an even stricter emission standard of our own limited to 50% of legally accepted concentration standard, and we are planning to continue our investments and efforts in finding new technologies to minimize pollutant emission

Extraneous substance

Based on 2015

| Class | Unit | Emission Allowance Criteria | Emission Concentration | Pollutant Emission Concentration to the Allowance Criteria (%) |

|---|---|---|---|---|

| PH | - | 5.8 - 8.6 | 6.70 | within standard range |

| SS | ㎖/ℓ | 80 | 5.40 | 6.8% |

| COD | 90 | 36.50 | 40.6% | |

| N-H Extraneous substance(mineral) | 5 | 0.28 | 5.6% | |

| N-H Extraneous substance(animals and plants) | 30 | 0.44 | 1.5% | |

| CN | 1 | 0.00 | 0.1% | |

| CU | 3 | 0.33 | 0.11% | |

| MN | 10 | 0.15 | 0.5% | |

| Fe | 10 | 0.12 | 1.2% | |

| T-N | 60 | 12.96 | 21.6% | |

| T-P | 8 | 1.18 | 14.8% | |

| Ni | 5 | 1.10 | 2.0% | |

| ABS | 5 | 1.18 | 3.6% |

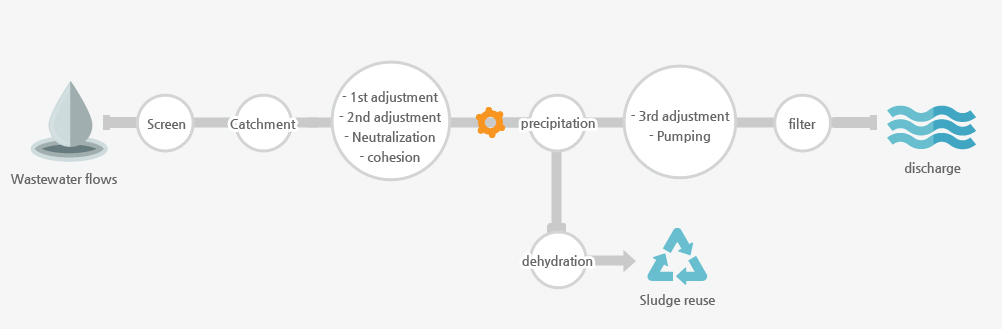

wastewater processing process

Safety/ Disaster Prevention

Interflex Inc. is making continuous efforts to establish a zero accident site and to form a healthy and pleasant workplace.

Establishment of integrated control center for emergency

Interflex Inc. has been operating an integrated control center to respond to emergency situation.

The control room is equipped with a system to perform integrated monitoring of overall information factors such as fire protection facility, utilities, weather information, gas/chemical substances etc., which enables us to be prepared for possible emergency.

Especially 24 hour monitoring is in place with detection sensor and CCTV in order to prevent chemical substance related accidents, and chemical substance is being prevented from being injected into streams by installation of storm water exclusion system to ensure that chemical leakage is automatically transferred to our own wastewater treatment plant.

PSM(Process Safety Management) Enforcement

Interflex Inc. is implementing PSM in order to eliminate fundamental causes of accidents such as fire/explosion and leakage and to prevent other significant industrial accidents.

We’re ensuring safe management of progress in compliance with PSM requirements from the design phase of new tasks to establishment of risk assessment and risk management system, introduction of facilities, progress change control and the commissioning.

Process Safety

12 elements

- 1Safety data regarding process

- 2risk assessment

- 3safety guide

- 4facility check and maintenance

- 5inspection prior to operation

- 6safety management for contractor

- 7workers training

- 8safety work permit

- 9item control for change

- 10internal inspection

- 11accident investigation

- 12emergency action

Establishment of Win-Win Partnership System (safety health support activities)

Interflex Inc. has contributed a lot to enhancing safety awareness and reducing disaster rates of our subcontractors by entering into a mutual corporation partnership for safety and health.

Also, we’re operating the safety/health conference on a monthly basis to discuss safety/health issues with our subcontractors, and are committed to execution of safety rules to ensure all employees’ safety awareness as part of our corporate culture.

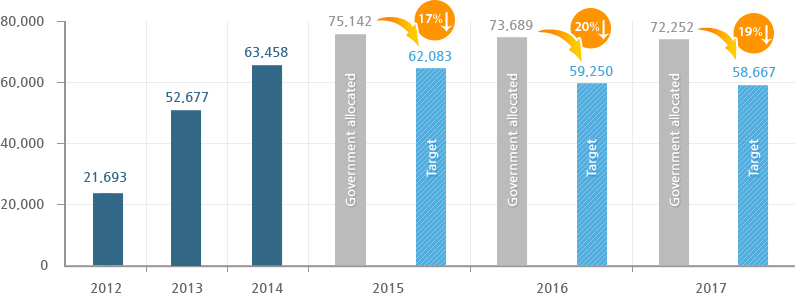

Greenhouse Gas Management

In accordance with 『Act on Allocation and Trading of Greenhouse Gas Emission』, Interflex Inc. is currently preparing and reporting the government of our Greenhouse Gas Emission Statement certified by a third party organization as was selected one of the carbon credit allocation companies for the 1st Planning Period of Emission Trade System(ETS) (The Ministry of Environment Notification No.2014-162),

Greenhouse Gas Emission

* Based on our Smart Center Standards appointed with carbon credit system in place [Emission: tCO2eq]

What is Conflict Minerals law?

The US government has codified four natural resources of gold, tin, tungsten and tantalum originated from 9 counties including Democratic Republic of Congo as “Conflict minerals”, determining that these minerals are being used as the financial source for armed forces of DRC.

The “Conflict Mineral Law” requires US and certain foreign companies, which are publicly offered in US Securities and Exchange Commission (SEC), to report and make public the use of so-called “conflict minerals” in the process of production or manufacturing of their products either self-produced or outsourced, and to disclose the country of origin and related description.